Details

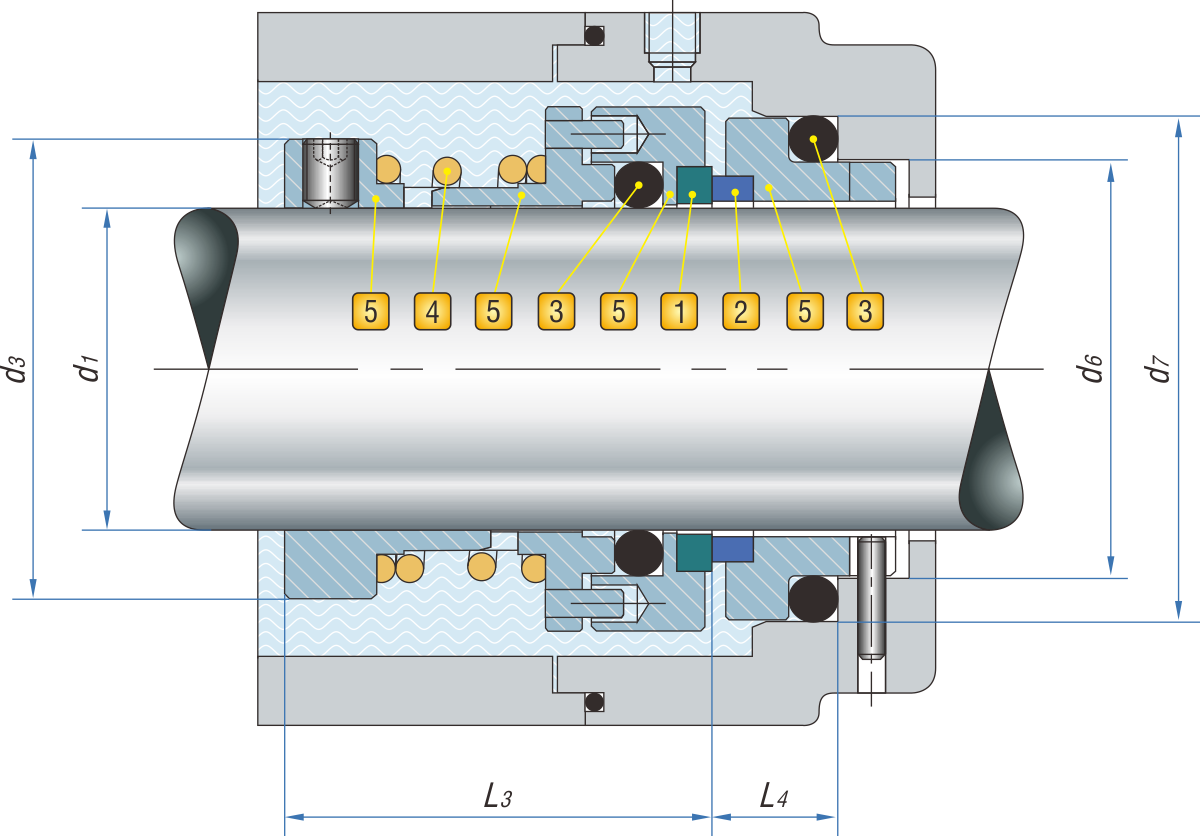

The TNG TG124 Mechanical Seal is a versatile and durable parallel spring-driven seal, designed with extended material combination options to enhance sealing efficiency in sewage treatment, low-corrosive media such as oil, and the chemical industry. With O-Ring pusher construction and single seal configuration, this seal ensures high reliability in demanding industrial applications.

Featuring drive lugs for improved stability and bi-directional operation, the TG124 offers consistent performance in various environments.

🔑 Key Features

✅ Unbalanced Mechanical Seal: Engineered for optimal sealing efficiency.

✅ Various Rotary Ring Material Options: Provides customized solutions for different applications.

✅ Drive Lugs for Enhanced Stability: Ensures secure and long-lasting performance.

✅ Bi-Directional Operation: Suitable for both clockwise and counterclockwise rotation.

💻 Technical Specifications

-

Shaft Diameter: 20 mm to 95 mm

-

Pressure Range: Up to 1.2 MPa (174 psi)

-

Temperature Range: -20°C to +180°C (-4°F to 356°F)

-

Sliding Velocity: ≤ 15 m/s (49.2 ft/s)

Note: The operating pressure, temperature, and sliding velocity depend on the seal material combination.

💡 Combination Materials

Rotary Face:

-

Reaction Bonded Silicon Carbide (RBSiC) O

-

Sintered Silicon Carbide (SSiC) O1

-

Tungsten Carbide with Ni-Binder W

Stationary Seat:

-

Reaction Bonded Silicon Carbide (RBSiC) O

-

Sintered Silicon Carbide (SSiC) O1

-

Tungsten Carbide with Ni-Binder W

-

Carbon Graphite (Resin Impregnated) AK

Auxiliary Seal:

-

Fluorocarbon Rubber (FKM) V

-

Ethylene Propylene Rubber (EPDM) E

-

Perfluorocarbon Rubber (FFKM) K

Spring & Metal Parts:

-

Spring:

-

GrNi-Steel (AISI 304) F

-

GrNiMo-Steel (AISI 316) G

-

-

Metal Parts:

-

GrNi-Steel (AISI 304) F

-

GrNiMo-Steel (AISI 316) G

-

🏭 Applications

✔ Petrochemical & Sewage Treatment Industry: Suitable for wastewater and oil processing applications.

✔ Low Solids Content or Viscous Media: Ideal for various industrial fluid-handling processes.

✔ Sewage Pumps, Chemical Pumps, Screw Pumps: Ensures effective sealing performance in challenging conditions.

✔ Other Rotating Equipment: Compatible with a range of industrial machinery.

🌟 Benefits

🌟 Reliable Performance: Built for efficient and durable operation in demanding environments.

🌟 Enhanced Stability: Incorporates rugged drive lugs for secure operation.

🌟 Long-Lasting Construction: Manufactured using high-quality materials for an extended lifespan.

🌟 Versatile Application: Adaptable to multiple industrial sectors and pump types.

🚀 Choose the TNG TG124 Mechanical Seal for superior sealing performance and reliability. Designed for petrochemical, sewage treatment, and chemical processing industries, this seal offers exceptional efficiency in industrial applications.

#TNGMechanicalSeal #TG124 #ParallelSpringSeal #IndustrialSeals #ReliableSealingSolution #SupplierMalaysia #PumpSeals

View more about ⚙️TNG Mechanical Seal – TG124 Parallel Spring Mechanical Seal🌟 on main site