Details

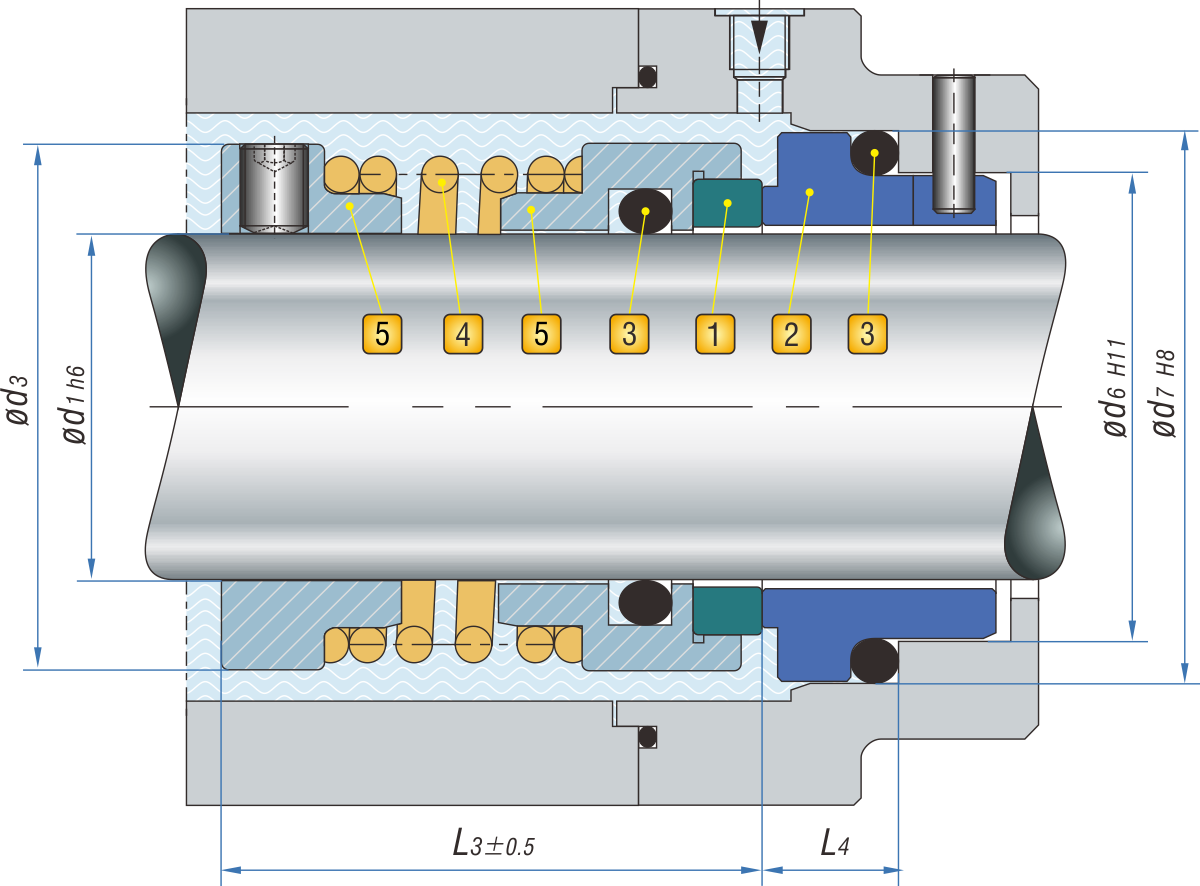

The TNG TG1597 Mechanical Seal is a spring-driven, mono-directional seal designed for varied industrial applications. Driven by a parallel spring system, this seal operates dependent on the shaft's rotation, functioning either clockwise or counterclockwise.

Featuring different rotary ring and auxiliary seal material options, it is engineered to adapt to multiple operating conditions. Widely used in marine, textile, pulp & paper, refrigeration compressors, and wastewater treatment industries, it delivers superior performance and durability.

Compliant with UK standards, the TG1597 ensures reliable and efficient sealing in demanding environments.

🔑 Key Features

✅ Various Rotary Ring Material Options: Provides flexibility for different applications.

✅ Spring-Driven System: Ensures stable and efficient torque transmission.

✅ Mono-Directional Operation: Designed to function in a single rotation direction.

✅ Global Standards Compliance: Conforms to UK industry standards.

💻 Technical Specifications

-

Shaft Diameter: 20 mm to 120 mm / 0.625'' to 4.000''

-

Pressure Range: Up to 1.0 MPa (145 psi)

-

Temperature Range: -20°C to +220°C (-4°F to 428°F)

-

Sliding Velocity: ≤ 15 m/s (49.2 ft/s)

Note: The operating pressure, temperature, and sliding velocity depend on the seal material combination.

💡 Combination Materials

Rotary Face:

-

Reaction Bonded Silicon Carbide (RBSiC) O

-

Sintered Silicon Carbide (SSiC) O1

-

Tungsten Carbide with Ni-Binder W

-

Cr-Steel (Solid) E

Stationary Seat:

-

Reaction Bonded Silicon Carbide (RBSiC) O

-

Sintered Silicon Carbide (SSiC) O1

-

Tungsten Carbide with Ni-Binder W

-

Carbon Graphite (Resin Impregnated) AK

-

Carbon Graphite (Antimony Impregnated) AD

Auxiliary Seal:

-

Elastomer O-Rings:

-

FKM (V)

-

EPDM (E)

-

Tetrafluoroethylene Propylene Rubber (FEPM) (X)

-

Spring & Metal Parts:

-

Spring:

-

GrNi-Steel (AISI 304) F

-

GrNiMo-Steel (AISI 316) G

-

-

Metal Parts:

-

GrNi-Steel (AISI 304) F

-

GrNiMo-Steel (AISI 316) G

-

🏭 Applications

✔ Textile Printing & Petrochemical Industry: Handles varied liquid conditions.

✔ Low Solids Content or Viscous Media: Ideal for fluid processing applications.

✔ Printing & Dyeing Pumps, Sewage Pumps, Industrial Pumps: Ensures efficient sealing performance.

✔ Other Rotating Equipment: Suitable for diverse industrial applications.

🌟 Benefits

🌟 Reliable Performance: Engineered for efficiency and long-term durability.

🌟 Enhanced Stability: Features rugged construction for smooth operation.

🌟 Long-Lasting Construction: Built with high-quality materials for extended service life.

🌟 Versatile Application: Adaptable to multiple industries and pump types.

🚀 Choose the TNG TG1597 Mechanical Seal for exceptional sealing performance and durability. Designed to withstand challenging industrial environments, this seal is the perfect solution for marine, textile, and wastewater treatment applications.

#TNGMechanicalSeal #TG1597 #ParallelSpringSeal #IndustrialSeals #ReliableSealingSolution #SupplierMalaysia #PumpSeals

View more about ⚙️TNG Mechanical Seal – TG1597 Parallel Spring Mechanical Seal🌟 on main site