Details

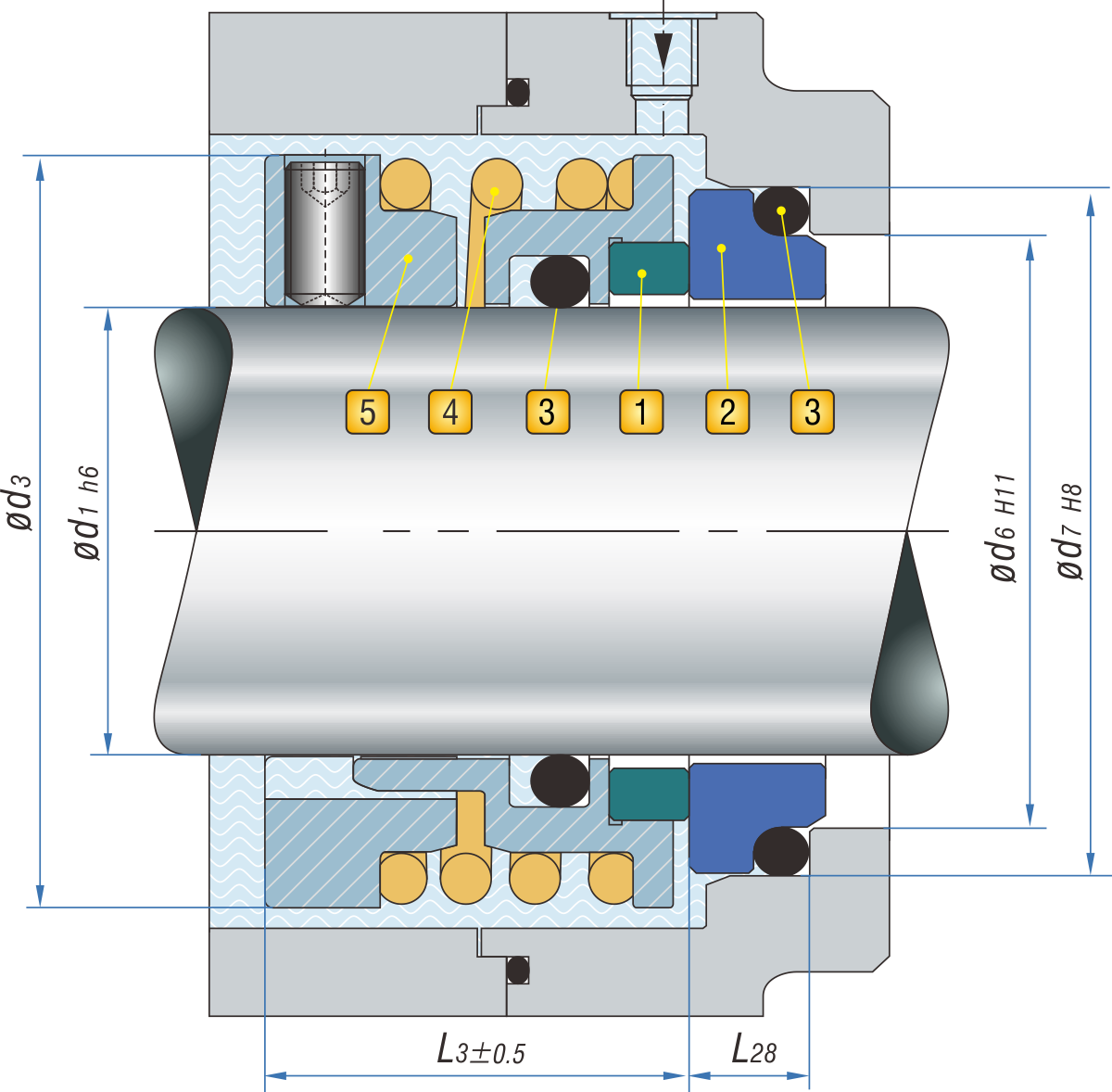

The TNG TG109G Mechanical Seal is designed with drive lugs for a rugged and reliable drive, making it ideal for dirty and viscous liquid conditions. Featuring various rotary ring and auxiliary seal material options, this seal is widely used in textile, pulp & paper, and wastewater treatment industries. It conforms to EN 12756 standards and shares the same working dimensions as comparable industry models.

🔑 Key Features

✅ Various Rotary Ring Material Options: Provides flexibility for diverse applications.

✅ Drive Lugs: Ensures secure and stable drive transmission.

✅ Bi-Directional Operation: Functions independent of shaft rotation direction.

✅ Global Standards Compliance: Conforms to EN 12756.

💻 Technical Specifications

-

Shaft Diameter: 20 mm to 100 mm

-

Pressure Range: Up to 1.0 MPa (145 psi)

-

Temperature Range: -20°C to +220°C (-4°F to 428°F)

-

Sliding Velocity: ≤ 15 m/s (49.2 ft/s)

Note: The operating pressure, temperature, and sliding velocity depend on the seal material combination.

💡 Combination Materials

Rotary Face:

-

Carbon Graphite (Resin Impregnated) AK

-

Carbon Graphite (Antimony Impregnated) AD

-

Reaction Bonded Silicon Carbide (RBSiC) O

-

Sintered Silicon Carbide (SSiC) O1

-

Tungsten Carbide with Ni-Binder W

Stationary Seat:

-

Reaction Bonded Silicon Carbide (RBSiC) O

-

Sintered Silicon Carbide (SSiC) O1

-

Tungsten Carbide with Ni-Binder W

Auxiliary Seal:

-

Nitrile Butadiene Rubber (NBR) P

-

Fluorocarbon Rubber (FKM) V

-

Ethylene Propylene Rubber (EPDM) E

-

Tetrafluoroethylene Propylene Rubber (EPDM) X

Spring & Metal Parts:

-

Spring:

-

GrNi-Steel (AISI 304) F

-

GrNiMo-Steel (AISI 316) G

-

-

Metal Parts:

-

GrNi-Steel (AISI 304) F

-

GrNiMo-Steel (AISI 316) G

-

🏭 Applications

✔ Petrochemical Industry & Sewage Treatment: Handles challenging liquid conditions.

✔ Low Solids Content or Viscous Media: Ideal for heavy-duty applications.

✔ Sewage Pumps, Chemical Pumps, Screw Pumps: Ensures reliable operation.

✔ Other Rotating Equipment: Suitable for diverse industrial machinery.

🌟 Benefits

🌟 Reliable Performance: Engineered for efficiency and durability.

🌟 Enhanced Drive Stability: Features rugged drive lugs for added reliability.

🌟 Long-Lasting Construction: Built with premium materials for extended service life.

🌟 Versatile Application: Adaptable to multiple industries and pump types.

🚀 Choose the TNG TG109G Mechanical Seal for exceptional performance and durability. Designed to withstand challenging industrial environments, this seal is the perfect solution for textile, pulp & paper, and wastewater treatment applications.

#TNGMechanicalSeal #TG109G #ParallelSpringSeal #IndustrialSeals #ReliableSealingSolution #SupplierMalaysia #PumpSeals

View more about ⚙️TNG Mechanical Seal – TG109G Parallel Spring Mechanical Seal🌟 on main site